WALLA WALLA, Wash. — It’s the height of the harvest in the Walla Walla Valley, and Artifex is humming along at a pace that could be described as a controlled frenzy.

Six full-time staff and a harvest crew of 15 interns are scrubbing tanks, dragging hoses, cleaning the press, doing pump overs, hosing down the floors and all the other tasks that come along with processing 700 tons of fruit in a single season. That’s a lot of fruit, when you consider that 700 tons yields about 44,000 cases of wine, which is about as much as the 25 wineries in the Dundee Hills American Viticultural Area produce among them.

Artifex, celebrating its 10th harvest this year, is the brainchild and partnership of an illustrious trio from the local wine industry: Jean-François Pellet, who serves as managing partner of Artifex, is the winemaker for Pepper Bridge Winery and Amavi Cellars; Norm McKibben, a viticulturist of Pepper Bridge, Seven Hills, and Les Collines vineyards fame; and Rick Middleton, owner of Cadaretta Wines and the Southwind Vineyard, are not as involved in the day-to-day operations at Artifex but serve as a guiding force.

Artifex a full-service facility

A decade ago, the group saw the need for a premium custom crush facility that would provide a full range of services, and Artifex opened its doors in 2006. The menu of services includes winemaking functions such as topping, racking, blending and chemical additions, and fruit processing services that include sorting, destemming, crushing and pressing.

Once the fruit is pressed, Artifex can provide barrel aging of wines as well as barrel maintenance, comprehensive laboratory services and quality control monitoring. When the wine is ready to be bottled, there are bottling and labeling services available. And throughout the process, there’s the required inventory and production tracking.

However, general manager Ariane Rizzo is emphatic that Artifex does not actually make any wine.

“We are a grape-to-bottle facility,” she told Great Northwest Wine. “We receive and process fruit, we do fermentation, barrel aging and bottling. We don’t source the grapes, and we don’t sell wine. All of our clients are required to have their own winemakers. We rely on the clients’ winemakers to provide us with written instructions all the way through the process.

“It’s quite a bit of work for the winemakers because they have to clearly think through everything they want us to do with their wine,” she added. “We don’t have our own winemaker on staff, and we don’t counsel our clients about winemaking.”

Under young management

Rizzo is clear, in control, everywhere at once, and noticeably young. At 28, this is her sixth harvest at Artifex, and she’s served as the general manager for three years. Arriving from New York City with a degree in graphic design and television, she reinvented herself in the world of wine.

In 2011, she decided she wanted to work in a winery. She knew it’s normal to start as an intern, so she applied everywhere she could think of.

Artifex hired her for three months as a harvest cellar intern. Interns came and went over the months and years, and Rizzo found herself still there.

“As different people left I started filling all the various positions here, so I worked in the lab, the cellar, the administrative assistant job, and all of a sudden I was the person who had done everything here and was familiar with the clients,” Rizzo said. “So I moved into the GM role, a little too young, at age 25.”

A key member of her team is Travis Maple, the cellarmaster at Artifex since May. He’s been in the wine industry for 15 years, starting out with Chateau Ste. Michelle and later as assistant winemaker for J. Bookwalter Wines before landing at Artifex.

“It’s fun here, with all the different clients we have, and all the interns, and being able to train people how to make wine,” he said. “Because really, in order to get into the industry, you have to have some experience, and we have a fantastic internship program here that allows me to help teach people how to do all the cellar operations.”

Typically, about half of the harvest interns come with prior experience, although this year Rizzo puts that estimate at closer to 70 percent. They come from all walks of life, from all over the country, and every year some come from abroad.

A place for women

Many of the interns are women, still a fairly uncommon sight on the crush pad and in the cellar.

“I really need to have both men and women in the cellar,” Rizzo said. “It provides a much more balanced environment, a much calmer environment.”

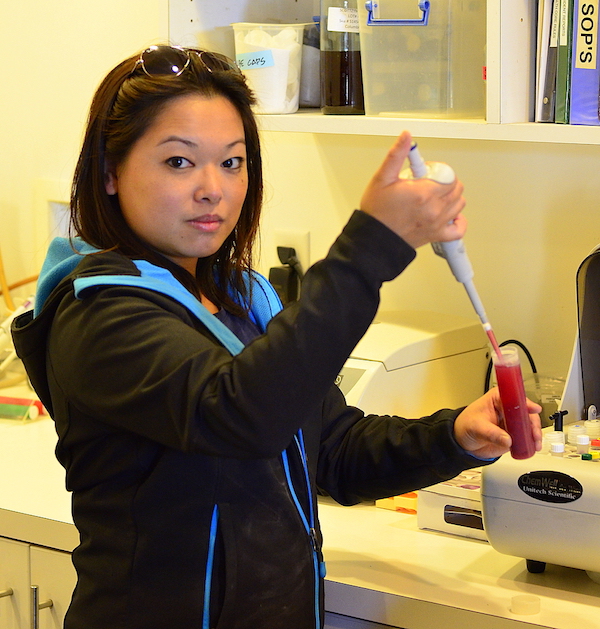

The operation also relies on the services of lab technician/enologist Fiona Mak, a recent graduate of Walla Walla Community College’s enology and viticulture program. She began as a sommelier in New York prior to going through in the WWCC program. Hired fresh out of school, Mak has worked hard to learn on the job.

She said she loves the role of enologist because “working in the lab you see a bigger piece of the pie than working in the cellar. In the cellar, you are basically moving wine from one process to another. Whereas in the lab, you work with the grapes from when they come in until the wine is in bottle. It’s a whole circle for me.”

Clients come in all sizes

Artifex works with a wide variety of clients, from a winery that makes just 200 cases a year to one that produces 15 different wines in-house. Clients are mostly local, but also include wineries from California, Oregon and Idaho. Some are too small to have their own facility, some are seeking a stable production environment so they don’t have to worry about staffing and production logistics and can concentrate on making and marketing their wines, and some have outgrown their current facilities and use Artifex as overflow production space.

They all are making premium or ultra-premium wines, starting at $20 a bottle. Artifex strives to be flexible and welcoming. Winemakers can be in the facility every day, at any time, to taste their barrels, pull samples or do blending trials. Some choose to be more physically involved, while others rely on Artifex staff as their labor.

During harvest season, Rizzo interacts with most of the winemakers daily.

“Our smaller clients require more of our time,” she said. “There’s a sense of their wine being really precious. It’s a smaller quantity, and it has to be perfect. The smaller wineries get far more personal attention, and we’re happy to do that. I try to say ‘yes’ to them as much as possible.”

At the conclusion of harvest, the interns move on, and the remaining staff gets down to work. During this period, most of the clients are out on sales trips, so the Artifex staff concentrates on barrel work. All of the barrels get a rack and return, where the wine is emptied from the barrels into a clean tank, the barrels are cleaned, and the wine is pumped back into barrel. For the largest client, that process takes six full weeks per vintage, it’s done it twice a year, and Artifex has two of that client’s vintages in house at all times.

That means that three entire months are spent on just the barrel work for that one client. And the same process is followed for each and every one of the 15 clients. Meanwhile, the work of blending older vintages, getting them ready for bottling, and the bottling itself occupy the rest of the year.

Of course, errors can creep in, as well as mistakes or accidents, because there are so many people working and so many different instructions from clients. What’s unique to a custom crush facility is that it works with many different brands. The worst kind of error, according to Rizzo, would be to mix up clients’ products, whether it be grapes or barrels or juice. Emphasizing that it rarely happens, she says that the most common problem is barrel accidents.

“We have 3,800 barrels in here and we have to move them around frequently, and it’s possible that they can be dropped,” Rizzo said. “They can roll off the rack, the forklift can slide, the barrel can come in from the factory with problems and we fill it without noticing them. But we’ve never had an injury report in 10 years, nothing more than cuts and scrapes and slips, so you can see that we don’t have many accidents.”

There’s also the constant concern about cross-contamination between clients, but so far Artifex reports that its has been free of brettanomyces and TCA, two organisms that can cause wine to spoil.

A secret service

All of this happens under conditions of strict confidentiality. Artifex will not name its clients, and no photographs are allowed in the facility that might in any way identify the client wineries. There are reasons for that.

“In the past, there was a misconception that if your wine was made at a custom-crush facility, we were making the wine for you, and you weren’t really the winemaker,” Rizzo explained. “We want to be very clear that our clients are making their own wine, and we’re just doing the labor. The clients are in total control, and that includes being in control of their image.”

Artifex goes to great lengths to keep their clients happy.

“What we do here is special,” Rizzo said. “It’s different from the way other custom-crush facilities operate in the amount of flexibility we have, and in that we cater to small- and medium-sized brands at higher price points.

“But to me, what makes Artifex special is really the people,” she continued. “Clients that we’ve had here for a long time are happy. Our clients’ winemakers have developed a rapport with each other. When they come in, they bounce ideas off each other. They are invested in our interns, they know who’s working on their wines. They’re very giving, they buy us T-shirts and meals, and we do everything in our power to make things work for them.”

Fantastic artical! It brings real insight to the civilian world of wine consumers who will now have a new appreciation of all the work and woman (and man power!) that goes into wine production. I am particularly thrilled for and very proud of my niece, the GM, Ariane Rizzo.Congratulations to her and all her colleagues at Artifex. There is no place else I’d rather be right now than on cite in Walla Walla with all of them to experience “The Crush!”

Awesome article. Hats off to the Washington state wine industry for its foresight.